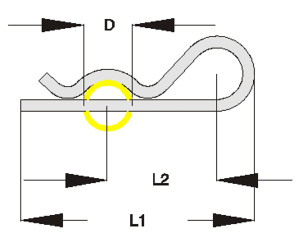

Of the Spring pin , also known as Spring splint pin, is used as a universal securing element to keep connected components in place. Spring pins hold nuts or crowns reliably in their position and prevent the elements from twisting. In addition, they are suitable in mechanical engineering for fixing axes and bolts against displacement. There are spring pins in different sizes for different uses. They can be used in many ways – for example in the automotive sector. The shape of the spring clip corresponds to the standard as standard DIN 11024 . The spring plug is designed to be resilient and thus locks into the material in a self-locking manner. It can be detached and reused if necessary.

Table of Contents

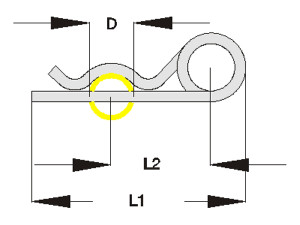

Offer spring clips for every use

Gutekunst Federn offers in Catalog By default Spring pins out Spring steel according to EN 10270-1 With galvanized surface and from stainless steel according to EN 12070-3-1.4310 for purchase directly from stock. Next to the Single spring pins according to DIN 11024 is there with the Double spring pins according to DIN 11024 also another version with double eyelet. This ensures better handling and less spring action. The selection of suitable sizes in the spring shop is based on the dimensions of the hole diameter, the outer diameter of the shaft and the tube and the total length and length of the resilient part.

Simply select spring clips according to DIN 11024 here in the spring shop and buy them directly

Select double cotter pins according to DIN 11024 in the spring shop and buy them directly

Other security elements on offer

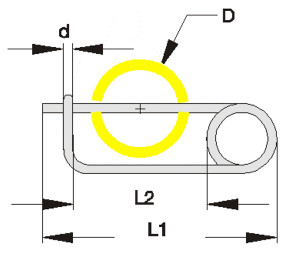

Focus needle

The focus needle, too Safety clip called, is mainly used in aviation to secure screw connections that can accidentally loosen due to vibrations. To prevent this, a screw with a cross hole at the end of the thread is used. The castle nut is screwed onto the thread end. In the next step, the focus needle is passed through the crown and the threaded hole, which prevents the screw from loosening. The advantage over spring clips: Users can remove the focus needle without tools and simply reuse it. Gutekunst Federn offers As standard, focus needles are made of spring steel EN 10270-1 with a galvanized surface and stainless steel EN 10270-3-1.4310 .

The focus needle, too Safety clip called, is mainly used in aviation to secure screw connections that can accidentally loosen due to vibrations. To prevent this, a screw with a cross hole at the end of the thread is used. The castle nut is screwed onto the thread end. In the next step, the focus needle is passed through the crown and the threaded hole, which prevents the screw from loosening. The advantage over spring clips: Users can remove the focus needle without tools and simply reuse it. Gutekunst Federn offers As standard, focus needles are made of spring steel EN 10270-1 with a galvanized surface and stainless steel EN 10270-3-1.4310 .

Linchpin

In the case of special requirements, special shapes such as linch pins according to DIN 11023 are suitable for structural or safety reasons. These are available in different designs. They are often used to secure shafts and pipes. In their basic form they consist of a springy steel bracket, the nut and a bolt or screw. The wire bracket is pivotably mounted in the prism-shaped base body. To secure the legs are interlaced with their own bracket. You have a self-locking effect.

Individual spring pins and safety elements

In addition to standardized spring clips and safety clips according to DIN, Gutekunst Federn also produces spring clips, clips and split pins for special applications in any desired shape. Do you need individual security elements? Then send your requirements as well as a sketch or drawing with the desired quantity to sales@gutekunst-co.com or contact our directly Technology department at (0049) 07123 960-193 .

Further information