The spring stiffness of compression springs, extension springs and torsion springs, also known as the spring constant or spring moment rate, is a measure of the hardness of the metal spring. It indicates how much force is required to compress the compression spring by a certain distance, to stretch the extension spring or to turn the torsion spring. The spring stiffness is given in newtons per millimeter (N/mm) and in newtons per millimeter (Nmm) for torsion springs. In mathematical terms, spring stiffness (R) is defined by Hooke’s law:

Formula spring stiffness / spring constant compression springs (N/mm)

R=\frac{Gd^{4}}{8D^{3}n}

Formula spring stiffness / spring constant tension springs (N/mm)

R=\frac{Gd^{4}}{8D^{3}n}=\frac{F-F0}{s}

Formula spring stiffness / spring torque rate torsion springs (Nmm)

R_{M}=\frac{M}{\alpha}=\frac{d^{4}E}{3667Dn}

Explanation of the formula:

α = Angle of rotation (°)

d = Wire diameter (mm)

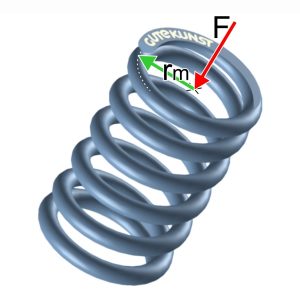

D = Average coil diameter (mm)

E = Modulus of elasticity (N/mm²)(E-modulus of various spring steels)

F = Spring force (N)

G = Sliding and shear modulus (N/mm²)(G-modulus of different spring steels)

F0 = Internal preload force

M = Torque (Nmm)

n = Number of spring coils (pieces)

R = Spring constant (N/mm)

RM = Spring moment rate (Nmm)

s = Spring deflection (mm) A higher spring stiffness means that a greater force is required in order to achieve the spring deflection, that a greater force is required to compress, stretch or rotate the metal spring by the same distance. The spring stiffness depends on various factors, such as the material, the wire diameter, the outer diameter of the metal spring and the number of coils.

Further information

- Gutekunst spring calculation program WinFSB

- Calculate spring force

- Spring work

- Spring steel properties

- Spring characteristic