Extension springs or helical tension springs absorb forces when they are pulled apart, which they release when they relax. Gutekunst Federn offers quick selection and procurement of extension springs in its catalog program on Federnshop.com 4280 different sizes in mild steel EN 10270-1 and stainless steel EN 10270-3-1.4310 directly from stock. And if no suitable extension spring is available in the shop, then manufacture Gutekunst Springs also any desired compression spring up to 12 mmm jet strength from the various spring steels in small quantities and large series.

Table of Contents

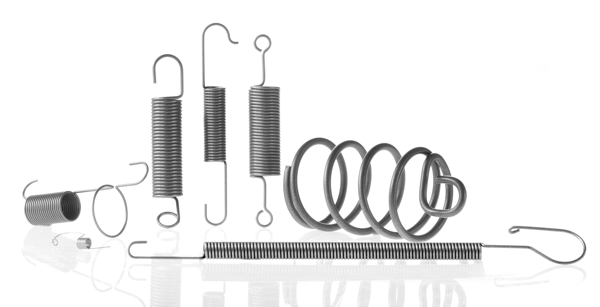

Properties of extension springs

Extension springs are made from round or oval spring steel wires. Most of the spring steel wire is formed into any desired shape in the cold forming process, either by winding it around a mandrel with a one-finger system or, in the case of fully automatic spring winding machines, with the help of several wire guide pins (two-finger or three-finger system). The eyelets are either formed directly during the winding process or set up in a subsequent operation ( Video spring production at Gutekunst Springs ). Extension springs are usually made cylindrical with a 1/1 German eyelet on each side. The manufacturing tolerances are based on DIN 2097, from quality level 1 (smallest tolerance) to quality level 3 (largest tolerance). The calculation of the extension springs is based on the EN 13906-2 standard. Gutekunst provides his spring calculation program WinFSB for free. There is also one here Formula collection for extension spring calculation .

Spring designs and loop shapes

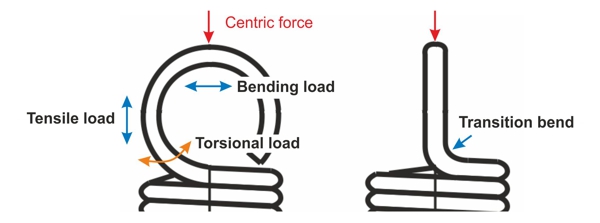

Besides the cylindrical extension spring design , with a linear spring characteristic, are also common conical or barrel-shaped Tension springs manufactured. With the conically tapered spring ends, in addition to a progressive spring characteristic, a longer service life is achieved. A degressive force curve cannot be generated via the tension spring design, this is only possible with a extension spring lever mechanism, such as. B. possible with a bed box. Come depending on the application different loop shapes for use. In addition to the classic loop shapes, such as the 1/1 German loop or hook eye, more resistant spring ends, such as the rolled up threaded bolts or screwed in threaded plugs that allow a longer service life. With conical spring ends, a longer service life for extension springs can also be achieved. Basically, extension springs are not fatigue-resistant due to the eyelets, as the eyelet connection on the transition bend is a major weak point. That is why it should be ensured with tension springs that the force acts centrally on the loops, otherwise the risk of an loop breakage increases.

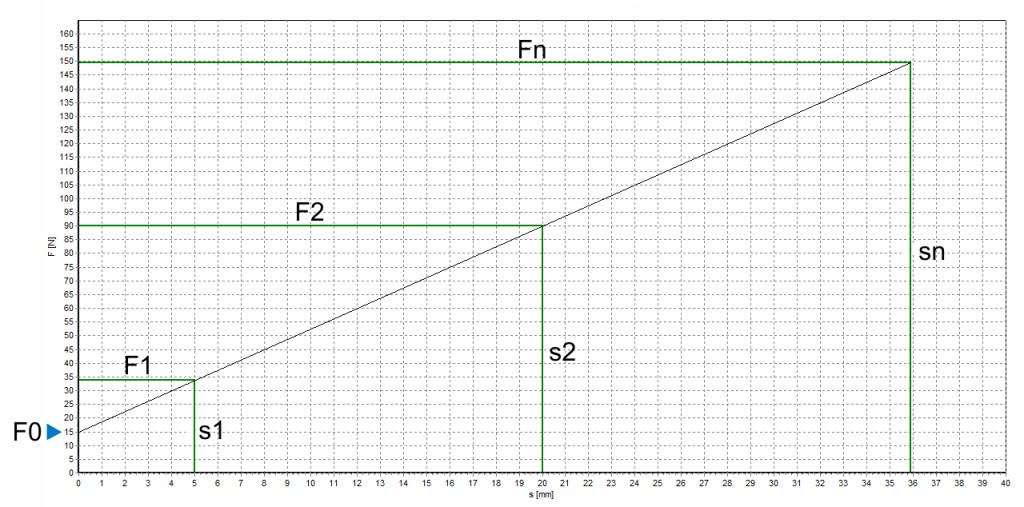

Preload

After the extension spring has been coiled and the eyelet formed, tempering takes place in order to reduce the internal stresses in the spring and to increase the shear elastic limit. In the case of the extension spring, a twist against the next turn creates a prestress during manufacture. This bias is largely desired because it minimizes the required operating length of the extension spring. However, when producing extension springs, the higher the preload, the higher the production costs. If no preload is desired in a tension spring, such as. B. in the case of a range spring, this can be removed almost completely afterwards by increasing the tempering temperature and tempering time. Thermoformed extension springs do not contain any preload either. In order to be able to guarantee the required spring properties, such as structural dimensions or force properties after manufacture, the preload (F0) or the mean coil diameter (D) is normally tolerated as a production compensation.

Relaxation, shear stress and spring forces

In addition, with extension springs, as with all metal springs, a certain percentage of the spring force is lost if the spring is loaded over a longer period of time at higher temperatures. This loss of strength is called relaxation , and it increases with increasing temperature and voltage. Since the relaxation, depending on the material and temperature, can mean a force loss of up to 20 percent, the greatest spring deflection should be a maximum of 80 percent of the permissible stress.

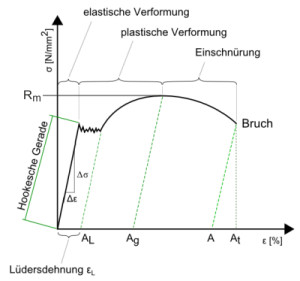

Exceeds, when the extension spring is loaded, that shear stress the permissible value of the yield strength Rp, permanent reduced preload or deformation occurs. Furthermore, attention should be paid to the resonance vibration of the tension spring; ideally, the vibrations of the excitation frequency are ten times smaller than the natural frequency of the spring, otherwise considerable increases in stress can occur.

The spring force / spring stiffness depends on the spring steel wire and the spring rate or. spring constant from. The spring rate also defines the ratio of spring force to spring travel. Basically, the dimensioning of the spring force can be influenced by the following measures:

Wire diameter (d) greater> spring harder

Coil diameter (De) greater> spring softer

Number of spring coils (n) greater> spring softer

The selection of the spring steel wire not only influences the spring force, but also offers the right material properties for the various spring applications. In addition to normal unalloyed spring steel wires, stainless spring steels, SiCr-alloyed valve spring wires, copper alloys for good electrical properties, nickel alloys for high heat and corrosion resistance, and titanium alloys for the highest demands in aerospace engineering are used. In addition, various surface treatments can be applied to optimize the requirements of the spring. In the case of extension springs, however, the application of a surface treatment is many times more difficult, since the surface in the spaces between the coils lying next to one another can only be applied with great effort.

Advantages of extension spring

The main advantages of the extension spring are the freedom from kinks, the possibility of central power transmission and the freedom from friction due to the elimination of guide elements such as sleeves or mandrels.

Disadvantages extension spring

The disadvantages of the extension spring are the size of the installation space, the sensitive point at the eyelet connection and the resulting total loss of spring force after an loop break.

Sometimes extension spring systems with several tension springs are also used. The most common application example are garage door spring assemblies connected in parallel in order to hold components with a larger mass in position with constant forces and spring moments.

Offer extension springs

Gutekunst Springs offers extension spring springs in 4280 different sizes directly from stock or individually manufactured from the various spring steels Up to 12 mm wire thickness in small quantities and large series. You can find the tension spring shop here . For an individual and non-binding extension spring offer, please send the required spring data to service@gutekunst-co.com or contact our quotation department directly at (+49) 07123 960-197.

Related Links: