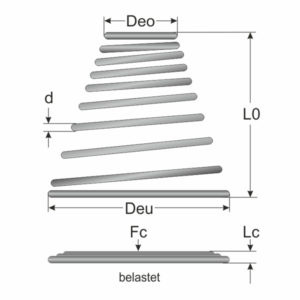

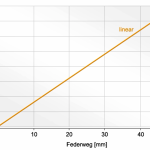

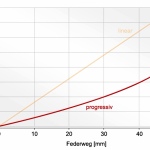

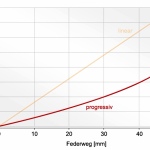

With conical compression springs, the diameter of the changes Design towards the ends, that is, gets bigger or smaller. They are mainly used when the installation space is limited in the axial direction. The specialty: the coils of conical compression springs interlock. This means that the block height corresponds to about twice the wire thickness and is therefore much smaller than with cylindrical ones compression springs . The springs can be linear or progressive spring constant be constructed. Usually this is spring rate or spring constant progressive. This means that the spring force increases with increasing load. A linear constant is achieved by changing the thread pitch according to the spring diameter. Then she stays spring characteristic constant during exercise. Conical springs are calculated according to EN 13906-1.

Types of conical compression springs

Cylindrical compression spring: A normal compression spring is a spring with a cylindrical design as well as a linear characteristic.

Simple conical compression spring: With this type of spring, which is often used as a contact spring or battery spring, the coil diameter is reduced from Deu to Deo. The spring characteristic is usually progressively increasing. The nib usually has an open and a curled end, also known as a pigtail.

Double conical compression spring: The double-conical compression spring is also known as a barrel spring, as both spring ends have a smaller coil diameter than the middle. She usually owns one progressive spring characteristic .

Mini block spring: The term mini block spring goes back to the adapted coil diameter:

If the mini block spring is compressed to a short length, most of the coils fit into one another without touching. This type of spring is often used in the axle suspension of a car – depending on the requirements for a linear spring rate with variable coils or for a progressive, increasing spring rate with constant coils. A big advantage is the small and space-saving block length of the spring. This is useful, for example, on the rear of a vehicle where a flat loading surface is required.

Waist spring: The coil diameter of the waist spring or double-conical compression spring increases towards the spring ends. The spring constant or spring characteristic is progressive. It is used, for example, to upholster armchairs, sofas and mattresses.

Beehive spring: The beehive spring is very good due to the reduced mass of the one-sided curled end dynamic properties .

If you need a conical compression spring, please send your spring data either via our inquiry form, or with the help of the PDF form or a drawing, simply to service@gutekunst-co.com. We will be happy to make you an offer.

For more information: