Leg springs, also known as torsion springs, are mechanical energy stores that absorb a torque when the legs are angularly / rotationally moved, which they release again when they are released. Gutekunst Federn offers quick selection and procurement of torsion springs in its catalog program on Federnshop.com 1600 different sizes in mild steel EN 10270-1 and stainless steel EN 10270-3-1.4310 directly from stock. And if there is no matching torsion spring available in the shop, then manufacture Gutekunst Federn also any leg spring you want up to 12 mm wire thickness from the various spring steels in small quantities and large series.

Table of Contents

Properties of torsion springs and torsion springs

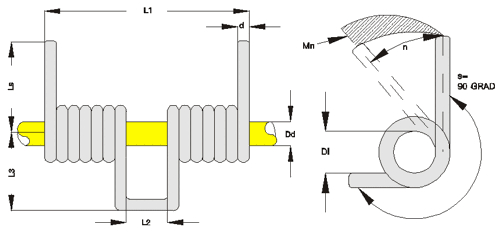

Torsion springs or torsion springs are made from round, oval or square spring steel wires. The Spring steel wire is mostly brought into any desired shape in the cold forming process, either by winding it around a mandrel or, in the case of fully automatic spring coiling machines, with the help of wire guide pins. The manufacturing tolerances are set from quality grade 1 (smallest tolerance) to quality grade 3 (greatest tolerance) according to DIN 2194. The torsion springs or torsion springs are calculated according to Standard EN 13906-3 . Gutekunst Federn provides the calculation for torsion springs or torsion springs Spring calculation program WinFSB at free disposal. A collection of formulas for the torsion spring calculation can be downloaded here.

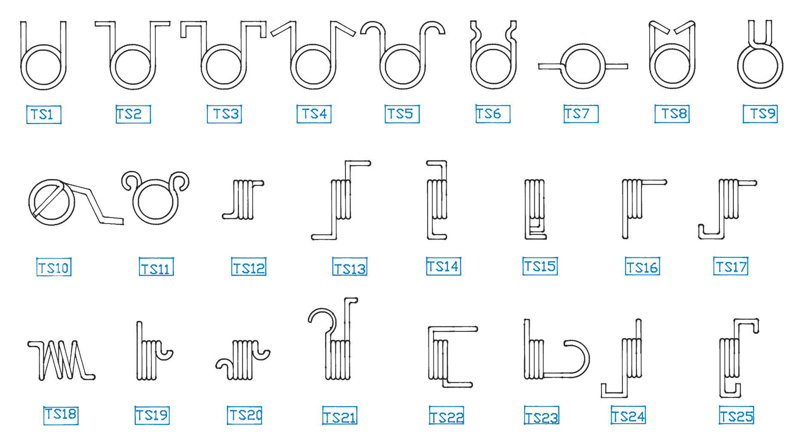

Torsion springs are usually cylindrical produced with a constant slope without winding spacings. Depending on the application, the legs can be led out tangentially, radially inside or outside, axially or axially parallel, etc. Below is a selection of possible leg shapes.

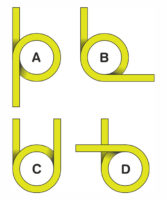

The torsion springs are available as standard in leg positions 0/360 (A), 90 (B), 180 (C) and 270 ° (D). However, any required leg position can be created using the number of turns.

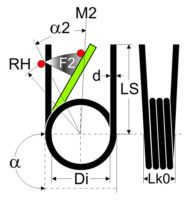

The spring power of torsion springs is given as torque in Nmm. In order to calculate the spring force in N, the lever arm (RH) (distance from the center of the spring body to the force application point on the leg) must be determined and calculated using the following formula.

The highest achievable spring force (Fn) then results from the division of the maximum torque (Mn) by the lever arm (RH):

The force that can be achieved at a given angle of rotation is calculated by dividing the highest spring force (Fn) by the maximum angle of rotation

multiplied by the angle of rotation:

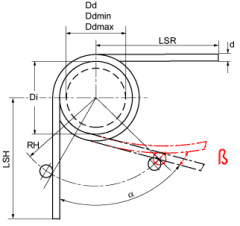

When calculating the spring force, the leg deflection (ß) must also be taken into account. This leg deflection increases, the longer the leg and the further away the force application point (RH) is from the center of the spring body.

In addition, torsion springs should only ever be loaded in the direction of the winding. For this reason, torsion springs are offered with identical left and right-hand winding. Torsion springs usually have one cylindrical spring body with a linear spring characteristic . We are not aware of any application examples with a progressive spring characteristic or conically tapering spring bodies.

Spring systems with torsion springs can be used in one Parallel connection will be realized. And because it works so well, with the double torsion spring even created its own type of spring to take advantage of the parallel connection.

The torsion springs from Gutekunst Federn catalog program are not started after winching, which has the advantage that leg bends and leg shortening can be easily made yourself at any time. Tempering of the torsion springs is generally not necessary if the bending stress only ever occurs in the direction of the winding. torsion springs may therefore only be loaded in the direction of the winding! The torsion springs usually work via a mandrel that holds the spring in place. However, since the spring body narrows during the rotary movement, the smallest and largest possible mandrel diameter must be taken into account when choosing the inner coil diameter (Di). The friction created by the guide influences the suspension behavior, which takes the form of a Hysteresis loop maps. Part of the spring work is converted into heat and is therefore lost.

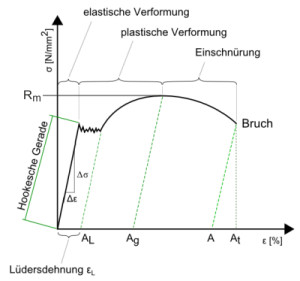

In addition, a certain percentage of the spring force is lost if the spring is loaded over a longer period of time at higher temperatures. This loss of strength is called relaxation and it increases with increasing temperature and tension. If, when the torsion spring is loaded, the bending stress exceeds the permissible value of the elongation limit, permanent deformation occurs, which is expressed in the unloaded position of the limb. In order to design the torsion spring for a longer service life, the stress correction factor “q” and the permissible stroke stress “σqh” should be taken into account when calculating. In addition, a surface strengthened by shot peening and a reduced load of up to 70 to 80 percent of the permissible bending stress support the service life.

The torque or the Spring stiffness depend on Spring steel wire and the Torque rate or torque constant. The torque rate also defines the ratio of the spring torque to the angle of rotation. Basically, the dimensioning of the torque can be influenced by the following measures:

Wire diameter (d) greater> spring harder

Outer coil diameter (De) greater> spring softer

Number of coils (nt) greater> spring softer

The selection of the spring steel wire not only influences the spring force, but also offers the right material properties for the various spring applications. In addition to normal unalloyed spring steel wires, stainless spring steels, SiCr-alloyed valve spring wires, copper alloys for good electrical properties, nickel alloys for high heat and corrosion resistance, and titanium alloys for the highest demands in aerospace engineering are used. There are also various surface treatments available to optimize the requirements of the spring.

Offer torsion springs

Gutekunst Federn offers torsion springs in 1600 different sizes directly from stock or individually manufactured from the various spring steels up to 12 mm wire thickness in small quantities and large series. You can find the torsion spring shop here . For an individual and non-binding torsion spring offer, please send the required spring data to service@gutekunst-co.com or contact our quotation department directly at (+49) 07123 960-197.

Related Links: