In metal springs, a loss of force occurs under permanent tension and higher temperatures, which is called relaxation. This loss of force increases with increasing temperature and load duration.

This loss of force is given as a percentage of the initial force “F1”.

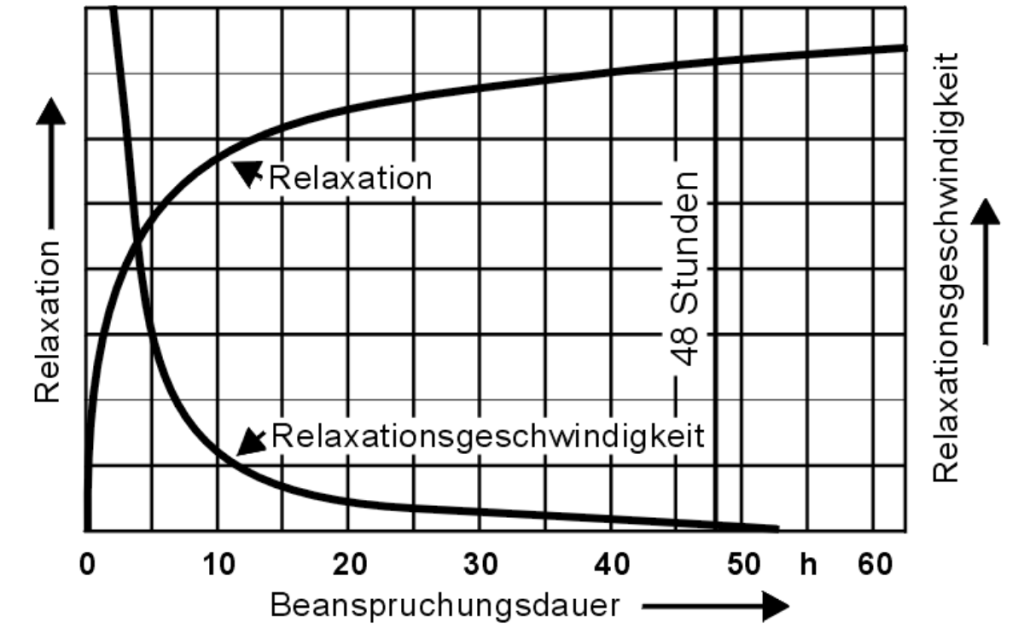

The following diagram shows the basic course of the relaxation and the relaxation speed.

The relaxation process is designed to last 48 hours, although relaxation is not complete after this time.

The material-dependent relaxation diagrams for determining the percentage loss of force in compression springs can be found in DIN EN 13906-1. Or read the force loss due to relaxation in the spring calculation program WinFSB. To do this, simply go to the compression spring calculation and click on the “Diagrams” button (Stress menu) after the calculation and read off the percentage loss of force due to relaxation.