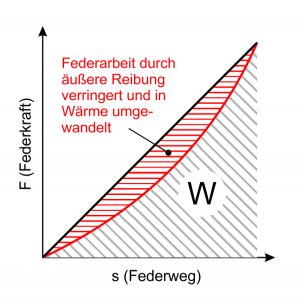

When the metal spring is tensioned, work is done, which is then released again when the tension is released. The spring work (W) always results as the area below the spring characteristic. The suspension behavior of steel springs can be influenced by external friction, which hinders the recovery. This change in effect is called hysteresis.

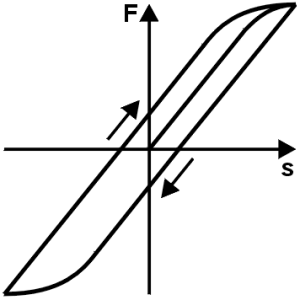

If the Metal springs this is expressed in the form of a hysteresis loop (see following picture). Part of the spring work is converted into heat by the friction and is then “lost”. Since this is undesirable when using metal springs, any friction should be structurally created by the arrangement and Shape of feathers be avoided. The elastic-plastic deformation behavior of a Material is subject to hysteresis. The hysteresis loop is obtained from the application in Stress-strain diagram .

For the interpretation of a suitable Compression- , Extension- or Torsion spring please contact our technical department directly by phone (+49) 035 877 227-13 or service@gutekunst-co.com .

For more information:

Setting amount compression springs

Spring calculation program WinFSB