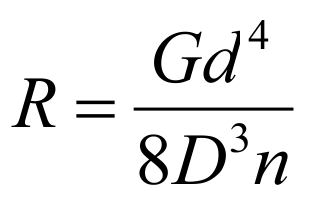

The spring rate, also called spring constant or spring hardness, depends on the spring material and the shape of the compression spring, extension spring or torsion spring. The formula for calculating the spring rate for cylindrical springs made of round

Calculate spring rate for cylindrical springs