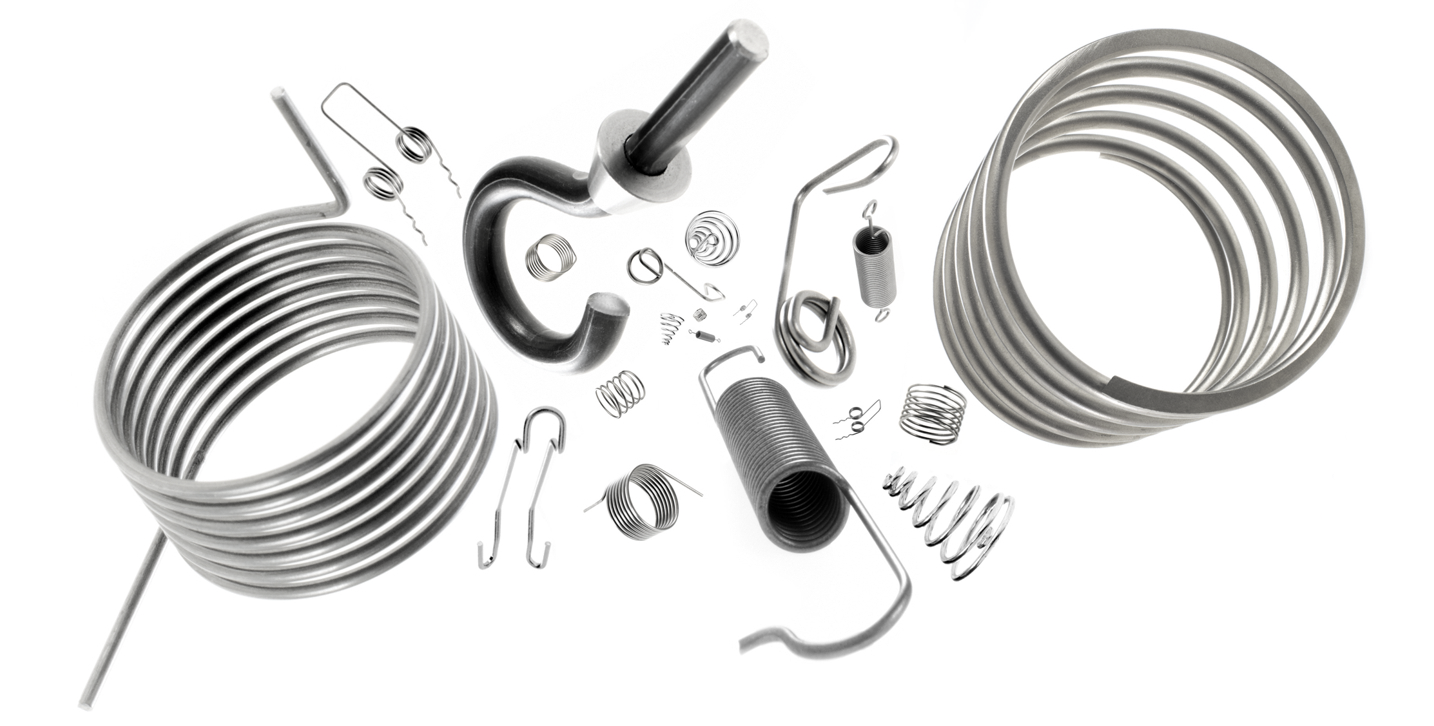

Compression springs, extension springs and torsion springs are typical C-parts for most companies: They are not the focus of the procurement process, but are used in almost all technical applications. The requirements for the springs are very versatile and individual. Compressive, tensile or bending load? Small or large? With shaped ends or straight? Extremely resistant or standard? Linear or progressive spring characteristic?

It is therefore important for the spring supplier to be able to react flexibly to customer requirements and to be able to supply individual special springs in addition to the standard springs that are quickly available from stock. Gutekunst Federn offers exactly this flexibility with its extensive catalogue programme with 12,603 spring sizes from stock and individual spring production up to 12 mm wire thickness.

If one of the catalogue springs in classic cylindrical design in standard steel EN 10270-1 and stainless 1.4310 fits, it is dispatched with a standard delivery time of five days.

If the application is more specific, then the spring is designed precisely to the installation situation and the individual requirements as a cylindrical spring, conical spring, barrel spring or beehive spring with variable spring characteristics and coil spacings. The design and calculation of compression, tension and torsion springs is carried out according to DIN EN 13906 and Gutekunst Federn‘s wealth of experience.

Gutekunst Federn offers all common spring steels, from simple spring steel wire according to EN 12070-1 to stainless steel wire V2A / V4A, valve spring wire VDSiCr, brass wire, copper beryllium and Hastelloy C4 to high-temperature materials such as Inconel X750, Nimonic 90 and Duratherm.

As a final surface treatment we offer chrome plating, zinc plating, thick film passivation, passivation, burnishing, Delta-Tone 9000, Teflon coating and many more. Various packaging solutions are used not only to protect against contamination, but also for automated separation of the springs if required.

For the selection and design of the suitable spring Gutekunst Federn offers – in addition to the in-house calculation and development service – versatile selection media and calculation tools. The paper catalogue is 430 pages long; in addition, the spring catalogue is available on CD and on the Internet at www.federnshop.com, each supplemented by the self-developed spring calculation program WinFSB and a CAD generator for 2D and 3D data.

For students, technicians, engineers and all those interested in springs, Gutekunst offers an internet forum at www.federn-forum.de. The moderator team of Gutekunst Federn answers there all questions around the topic “springs” and offers support in case of problems. In addition, interesting topics on spring design and production are regularly posted.

Founded in 1964, Gutekunst Federn is today one of the larger spring manufacturers in Europe with four company branches in Germany and France. Gutekunst maintains one of the largest ranges of springs from stock in Europe. With 320 employees, Gutekunst Federn supplies over 100,000 customers worldwide in the mechanical engineering, automotive, electrical, medical, aerospace, food, jewellery and cosmetics industries. With over 150 coiling and bending machines and a production volume of two million springs daily, Gutekunst Federn is an efficient and versatile spring supplier for spare parts, samples, small quantities and large series.