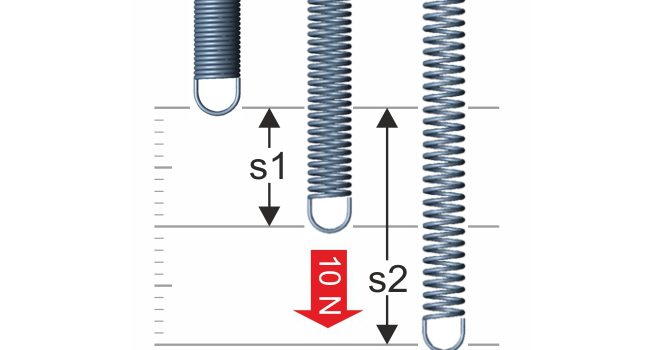

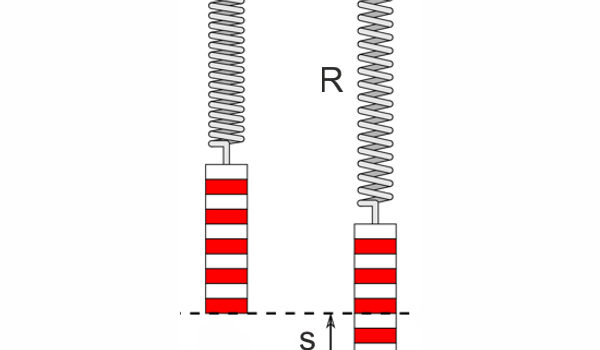

The tolerances for tension springs are defined in accordance with DIN 2097 (DIN EN 15800). Quality grade 1 describes the smallest tolerance zone (higher product price) and quality grade 3 the largest tolerance zone. Our tension springs are manufactured to

Tension spring tolerances