Of the Spring pin , also known as Spring splint pin, is used as a universal securing element to keep connected components in place. Spring pins hold nuts or crowns reliably in their position and prevent the elements from twisting.

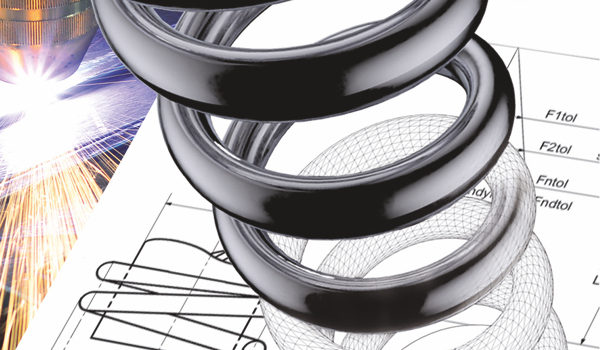

Spring pins and other safety elements