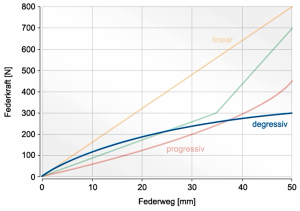

Metal springs are used in various designs. In addition to the cylindrical design, which is most commonly used, there is also the conical, barrel-shaped design or for special ones dynamic Compression spring applications the beehive spring. Each design has a special one spring characteristic which is described in more detail below. In addition to these spring designs, special spring characteristics can also be used with different winding distances and spring systems be generated.

Table of Contents

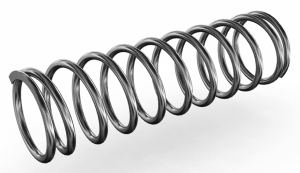

The cylindrical metal spring

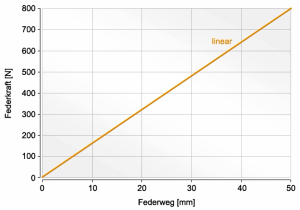

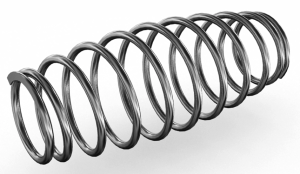

The most common classic design is the cylindrical metal spring. With this design, the spring characteristic is linear, ie the force is emitted evenly. This design is used for linear storage of potential energy and springback, such as valve springs, brakes, clutches and contact springs.

The conical and barrel-shaped metal spring

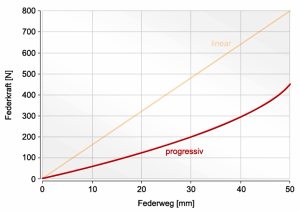

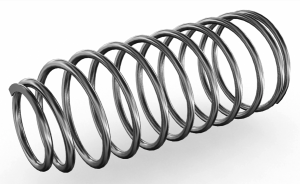

In the conical metal spring , which is used for a progressive force curve, increases the force development as the compression increases. This spring shape is often used with compression springs used in axle suspension, and offers at extension springs a longer service life.

The barrel and beehive spring

These spring shapes also have a progressive spring characteristic, but are used less often. The advantage of the barrel spring lies in the optimal use of the installation space, and with the beehive spring it is special dynamic properties due to the reduced moving mass at the conical spring end.

Combined compression spring designs

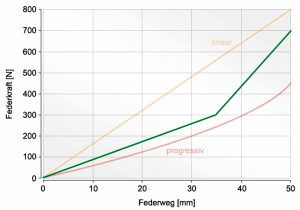

In addition to the classic spring designs and spring characteristics, combined compression spring designs and characteristics are also possible.

Degressive spring characteristic

A degressive spring characteristic, which reduces the development of force as the compression increases, is achieved with disc springs.

You can get further information and support for the optimal spring design here: