Spring systems are spring-technical applications made up of several individual springs, which together realize special tasks. These individually designed spring systems can be designed for a wide variety of applications. By selecting and arranging different springs, practically every desired force property and every spring characteristic produce. In addition to the classic spring systems – such as parallel connection and series connection – it is possible to achieve very special spring properties and spring characteristics using mixed connections.

Table of Contents

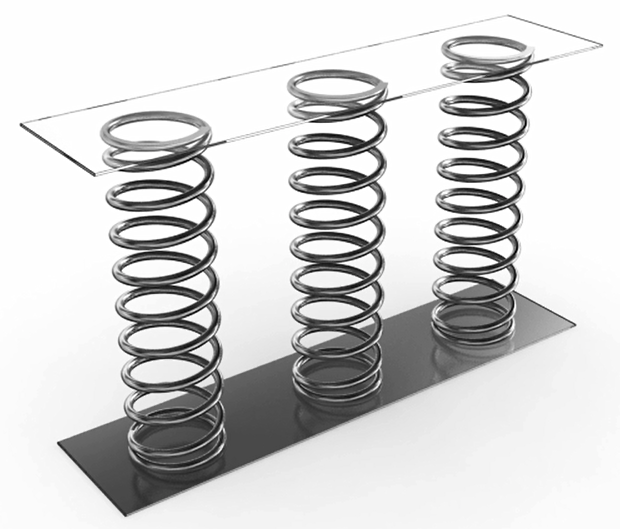

Parallel connection of metal springs

Most spring systems are parallel connections . When connecting in parallel, it is important to distribute the force acting on several springs. Whether the springs are placed next to one another or one inside the other depends on the space available. Springs standing next to each other should always be the same. The spring constant , or. spring rate of the individual springs add up and form a new replacement spring that realizes higher forces with a smaller spring deflection. This creates a harder spring with a greater spring constant and spring stiffness. With a parallel connection, the individual springs are also less stressed, which increases the service life and fatigue strength. Formulas for calculating the total spring travel, spring force and spring constant of a parallel connection of springs.

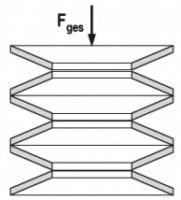

Series connection of metal springs

The series connection of single feathers occurs less often. The springs are installed one behind the other with intermediate layers. With the series connection, unlike the parallel connection, the force acting on each spring is given the same strength. This creates a replacement spring which has a smaller total spring constant or total spring rate than the spring constant of the individual springs and in which the spring travel of the individual springs is added. In this way, not only can a soft overall spring with a low spring stiffness and a slow increase in force be developed, but with the right selection of springs, specific spring forces can be achieved in specific tension states in a targeted manner in a series connection. Thus, any desired spring characteristic realize. Formulas for calculating the total spring travel, spring force and spring constant of a series connection of springs.

Mixing circuit metal springs

In the mixed circuit the properties of parallel connection and series connection are combined. For example, forces can be applied to several springs with one progressive spring characteristic by using different parallel connections arranged one above the other. In addition to this simple mixed circuit, spring systems can also be developed where the spring system first has the properties of a series connection and then later assumes the properties of a parallel connection. Formula for calculating the total spring constant of a mixed spring circuit.

Most spring systems come with compression springs realized. But there are also classic spring systems tension springs , such as garage door spring systems or folding mechanisms for bed boxes. In the case of the leg springs, the double torsion spring even a classic parallel connection has been implemented in a standardized manner.

Wave and disc spring columns

In addition to the spring systems made from round wire springs, there are also spring systems with wave and disc springs. The advantage of this type of spring is the greater force absorption in a small space, the disadvantage is a short spring deflection; this can only be compensated for by a larger wave spring column, which means that the space advantage is lost again. With spring systems made of round wire, the installation space for implementing the spring application may be larger, but with these spring systems any desired stress state can be realized linearly or progressively, and that with significantly lower production costs.

Gutekunst Federn has decades of experience in the design of spring systems. Please send your requirements to service@federnshop.com.

For more information: