Here is an overview of the different eyelet shapes for Extension springs after DIN EN 13906-2: 2013 with the respective loop properties. Extension springs should only be subjected to static loads. If higher loads are planned, bent eyelets should be avoided and rolled or screwed-in end pieces should be used. Is useful at more stressed extension springs also a life test under real operating conditions.

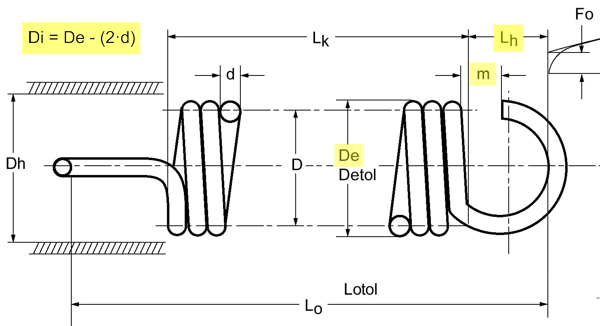

With the respective Loop properties please note the dimensions, for example the 1/1 German loop the value Lh (Distance between the inner edge of the eyelet and the spring body) should only be between 0.8 and 1.1 Di (inner coil diameter). In addition, with the specification m the eyelet opening width can be specified.

Additional information: Lh and m

(Lh = 0.8 to 1.1 Di)

Additional information: Lh

(Lh = 0.8 to 1.1 Di)

Additional information: m

(Lh ~ Di)

Additional information: none

(Lh ~ Di)

Additional information: m

Additional information: Lh and m

(Lh = 0.55 to 0.8 Di)

Additional information: m

(Lh ~ 1.1 Di)

Additional information: Lh and m

Additional information: Lh and m

Additional information: drawing!

Additional information: drawing!

Additional information: drawing!

Additional information: drawing!