The tolerances for tension springs are defined in accordance with DIN 2097 (DIN EN 15800). Quality grade 1 describes the smallest tolerance zone (higher product price) and quality grade 3 the largest tolerance zone. Our tension springs are manufactured to grade 2 (medium tolerance range) as standard.

The tolerances for tension springs are defined in accordance with DIN 2097 (DIN EN 15800). Quality grade 1 describes the smallest tolerance zone (higher product price) and quality grade 3 the largest tolerance zone. Our tension springs are manufactured to grade 2 (medium tolerance range) as standard.

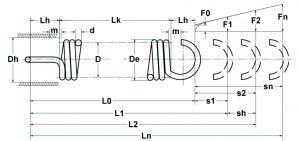

For tension springs, the coil diameter [D, De], the untensioned length [L0], the spring forces [F1, F2] as well as the eyelet position and the eyelet protrusion are tolerated. DIN 2097 provides tolerance specifications in tabular form (see below) for the coil diameter, the untensioned length and the eyelet protrusion. The tolerance values for the spring forces [F1, F2] and the eyelet position are calculated on the basis of coulter diagrams. The tolerance calculation can be carried out using the Gutekunst spring calculation program.

Table of Contents

1. tolerance coil diameter [D, De] Tension springs

The tolerance values for the coil diameter [D, De] of a tension spring can be read from the following table of values for quality grades 1, 2 and 3 based on the average coil diameter [D] and the coil ratio [w].

Winding ratio: w=\frac{D}{d} (D=mean winding diameter, d=wire diameter)

| D (mm) | Maximum tolerance (+/- mm) Winding diameter [D, De] |

||||||||

| Middle | Quality grade 1 |

Grade 2 (standard) | Grade 3 |

||||||

| Winding diameter | with winding ratio w | with winding ratio w | with winding ratio w | ||||||

| from – to | 4 – 8 | 8 – 14 | 14 – 20 | 4 – 8 | 8 – 14 | 14 – 20 | 4 – 8 | 8 – 14 | 14 – 20 |

| 0,63 – 1,00 | 0,05 | 0,07 | 0,10 | 0,07 | 0,10 | 0,15 | 0,10 | 0,15 | 0,20 |

| 1,00 – 1,60 | 0,05 | 0,07 | 0,10 | 0,08 | 0,10 | 0,15 | 0,15 | 0,20 | 0,30 |

| 1,60 – 2,50 | 0,07 | 0,10 | 0,15 | 0,10 | 0,15 | 0,20 | 0,20 | 0,30 | 0,40 |

| 2,50 – 4,00 | 0,10 | 0,10 | 0,15 | 0,15 | 0,20 | 0,25 | 0,30 | 0,40 | 0,50 |

| 4,00 – 6,30 | 0,10 | 0,15 | 0,20 | 0,20 | 0,25 | 0,30 | 0,40 | 0,50 | 0,60 |

| 6,30 – 10,00 | 0,15 | 0,15 | 0,20 | 0,25 | 0,30 | 0,35 | 0,50 | 0,60 | 0,70 |

| 10,00 – 16,00 | 0,15 | 0,20 | 0,25 | 0,30 | 0,35 | 0,40 | 0,60 | 0,70 | 0,80 |

| 16,00 – 25,00 | 0,20 | 0,25 | 0,30 | 0,35 | 0,45 | 0,50 | 0,70 | 0,90 | 1,00 |

| 25,00 – 31,50 | 0,25 | 0,30 | 0,35 | 0,40 | 0,50 | 0,60 | 0,80 | 1,00 | 1,20 |

| 31,50 – 40,00 | 0,25 | 0,30 | 0,35 | 0,50 | 0,60 | 0,70 | 1,00 | 1,20 | 1,50 |

| 40,00 – 50,00 | 0,30 | 0,40 | 0,50 | 0,60 | 0,80 | 0,90 | 1,20 | 1,50 | 1,80 |

| 50,00 – 63,00 | 0,40 | 0,50 | 0,60 | 0,80 | 1,00 | 1,10 | 1,50 | 2,00 | 2,30 |

| 63,00 – 80,00 | 0,50 | 0,70 | 0,80 | 1,00 | 1,20 | 1,40 | 1,80 | 2,40 | 2,80 |

| 80,00 – 100,00 | 0,60 | 0,80 | 0,90 | 1,20 | 1,50 | 1,70 | 2,30 | 3,00 | 3,50 |

| 100,00 – 125,00 | 1,40 | 1,90 | 2,20 | 2,80 | 3,70 | 4,40 | |||

| 125,00 – 160,00 | 1,80 | 2,30 | 2,70 | 3,50 | 4,60 | 5,40 | |||

2. tolerance untensioned length [L0] Tension springs

The tolerance values for the untensioned length [L0] of a tension spring with wound-in pretension can be read from the following table of values for quality grades 1, 2 and 3 based on the untensioned length [L0] and the winding ratio [w].

Winding ratio: w=\frac{D} {d} (D=mean winding diameter, d=wire diameter)

| L0 (mm) | Maximum tolerance (+/-) untensioned length (L0) | |||||

| Relaxed | Quality grade 1 | Grade 2 (standard) | Grade 3 | |||

| Length | with winding ratio w | with winding ratio w | with winding ratio w | |||

| from – to | 4 – 8 | 8 – 20 | 4 – 8 | 8 – 20 | 4 – 8 | 8 – 20 |

| < 10 | 0,30 | 0,40 | 0,40 | 0,50 | 0,60 | 0,70 |

| 10 – 16 | 0,40 | 0,50 | 0,50 | 0,60 | 0,80 | 1,00 |

| 16 – 25 | 0,50 | 0,60 | 0,60 | 0,70 | 1,00 | 1,30 |

| 25 – 40 | 0,60 | 0,80 | 0,80 | 0,90 | 1,30 | 1,60 |

| 40 – 63 | 0,80 | 1,10 | 1,10 | 1,30 | 1,80 | 2,20 |

| 63 – 100 | 1,10 | 1,50 | 1,50 | 1,80 | 2,40 | 3,00 |

| 100 – 160 | 1,50 | 2,00 | 2,00 | 2,40 | 3,00 | 4,00 |

| 160 – 250 | 2,00 | 2,50 | 2,50 | 3,00 | 4,00 | 5,00 |

| 250 – 400 | 2,50 | 3,00 | 3,00 | 4,00 | 5,00 | 6,50 |

| > 400 | 1 % of L0 | 1 % of L0 | 1.5 % of L0 | 1.5 % of L0 | 2 % of L0 | 2 % of L0 |

3. tolerance eyelet protrusion tension springs

The tolerance values for the maximum eyelet protrusion to the spring body sheath surface of the tension spring in accordance with DIN 2097 (DIN EN 15800) can be found in the following table of values for quality grades 1, 2 and 3.

Winding ratio: w=\frac{D} {d} (D=mean winding diameter, d=wire diameter)

| Maximum tolerance (+/- mm) Eyelet protrusion | |||

| Quality grade 1 | Grade 2 | Grade 3 | |

| w < 6 | 0,5 d | d | 2 d |

| w = 6-12 | 0,75 d | 1,5 d | 3 d |

| w > 12 | Manufacturer agreement | ||

4. tolerance spring force [F1, F2] tension springs

The tolerance of the tension spring for the spring force [F1, F2] can be calculated in the Gutekunst spring calculation program by specifying the dimensional data. Go to the spring calculation program and enter the spring data – material, eyelet shape (usually 1/1 German eyelet), wire thickness [d], outer coil diameter [De], untensioned length [L0], pretensioned length [L1] and tensioned length [L2] as well as the number of spring coils [n]) – in the input fields “according to dimension” for calculation. You can then read off the tolerance values (+/-) in the calculation result.

Related Links: