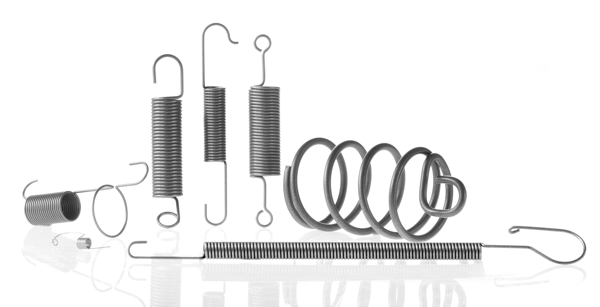

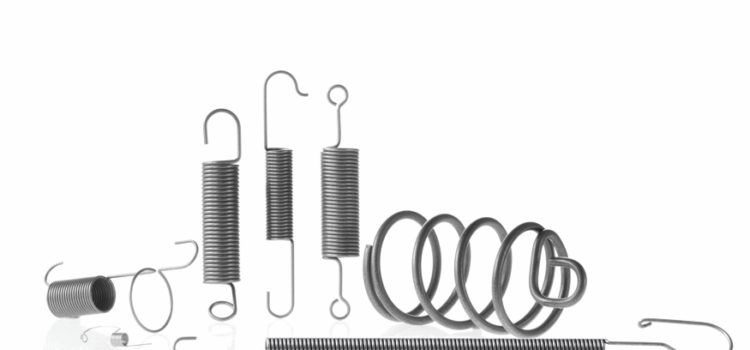

Metal springs are used in various designs. In addition to the cylindrical design, which is most commonly used, there is also the conical, barrel-shaped design or for special ones dynamic Compression spring applications the beehive spring. Each design has a

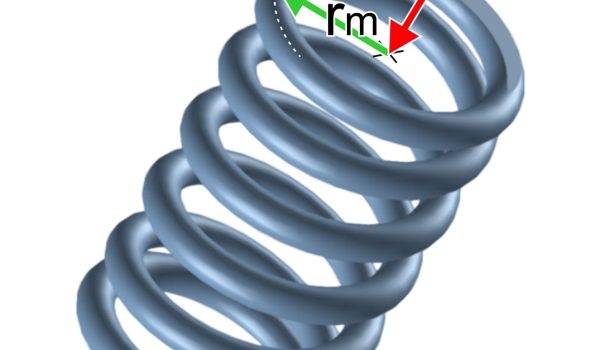

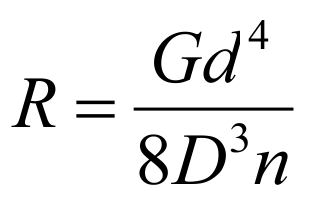

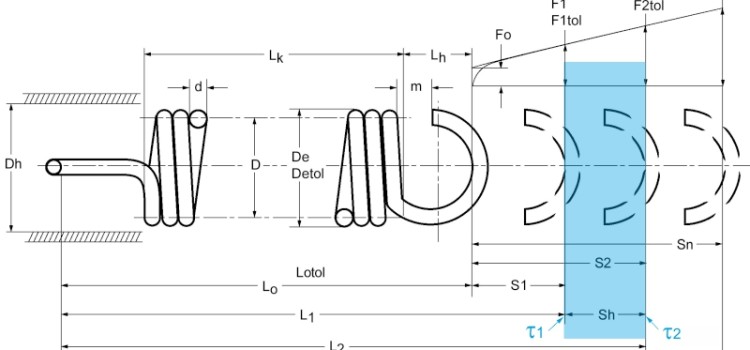

Design spring body