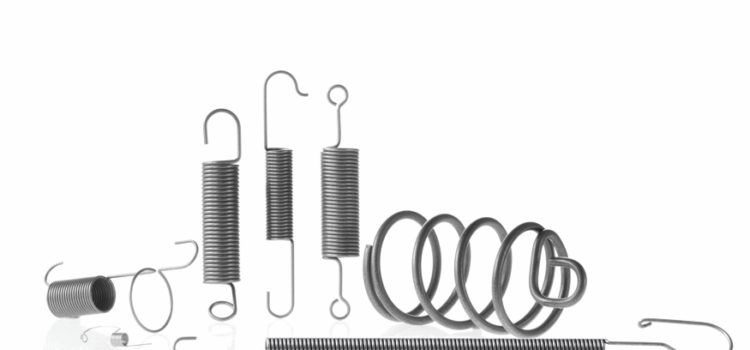

Whether spring steel, bronze or brass wire – everyone Spring material has a specific strength. This determines the degree of mechanical resistance, for example if it comes to plastic deformation or separation. The characteristic values for the strength can with

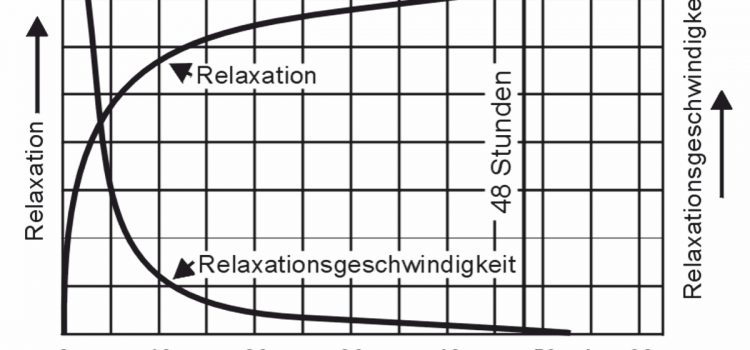

Spring materials with high fatigue strength