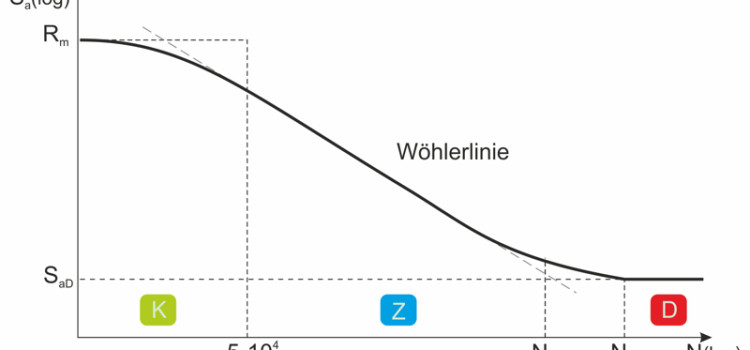

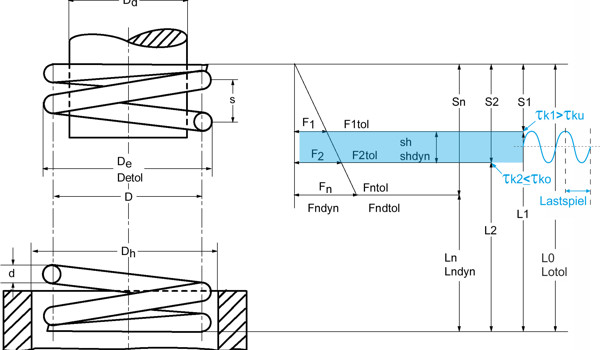

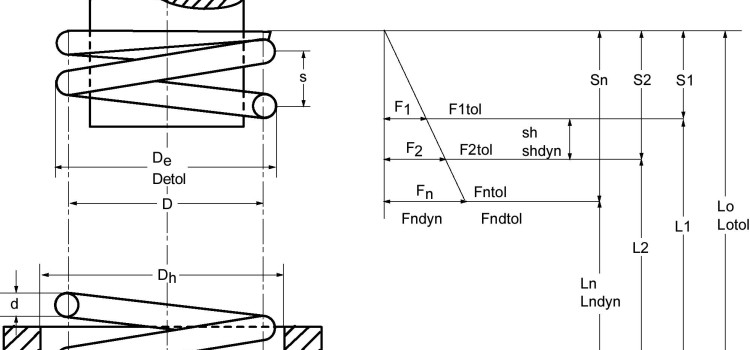

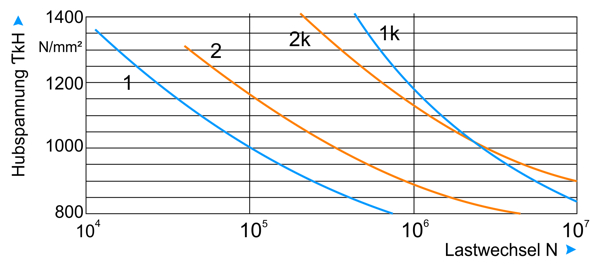

The term fatigue strength comes from materials science. It describes the deformation and failure behavior of an oscillating (dynamically) loaded material for a defined number of cycles. Especially at heavily used compression springs it is important to record the fatigue

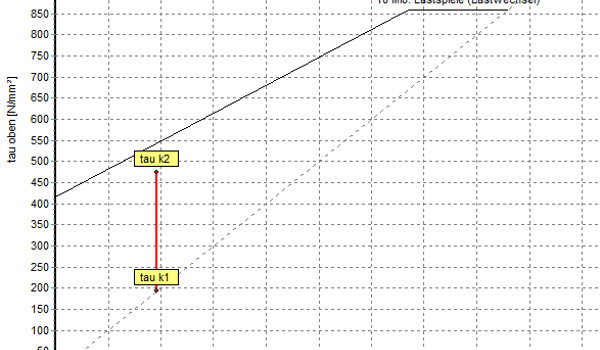

Fatigue strength