Compression springs, extension springs and torsion springs are typical C-parts for most companies: They are not the focus of the procurement process, but are used in almost all technical applications. The requirements for the springs are very versatile and individual.

Compression springs spring systems

To absorb forces and movements are sometimes also Spring systems used. Due to the different arrangement of Compression springs A wide variety of force properties can be generated. Simple spring systems are: Compression springs parallel connection The springs are arranged

Metal springs for extreme cases

Whether in corrosive liquids, at High temperature applications or at lowest temperatures , with dynamic or static loads, compressive, tensile or bending loads: With the Design of the metal spring in extreme cases there is more to be done than

Setting amount compression springs

Exceeds when the spring is loaded Shear stress the permissible value, a permanent deformation occurs, which manifests itself in the reduction of the unstressed length “L0”. This process is called “setting” in spring technology, which is associated with the properties

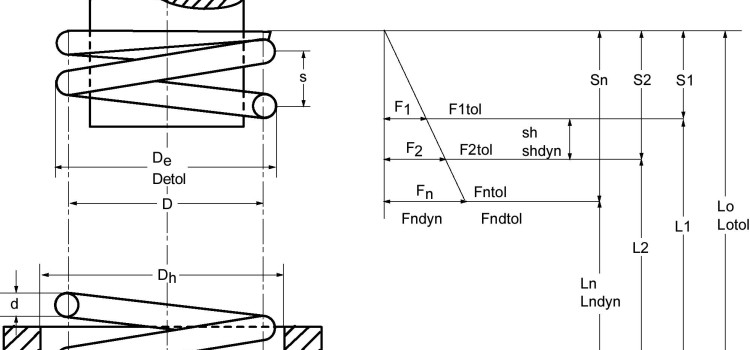

Function and strength verification for compression springs

Every spring design of a compression spring consists of two stages : 1. The proof of function, with the verification of the dimensions, spring rate, forces, spring travel and vibration behavior. 2. The proof of strength, with the verification of

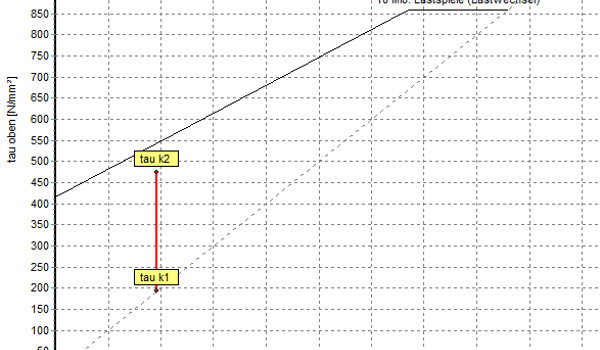

Goodman Chart

The Goodman diagram enables the representation of the Fatigue strength of coil springs. It can be traced back to the Smith chart. This is used to calculate the fatigue strength of dynamically stressed components where the load is pulsating or

Design of metal springs – Part 2 “Calculation

In the first part of this two-part series Gutekunst Federn informed about the basics of spring design. In this second part you will find the concrete calculation data for the design of compression springs, extension springs and torsion springs (torsion

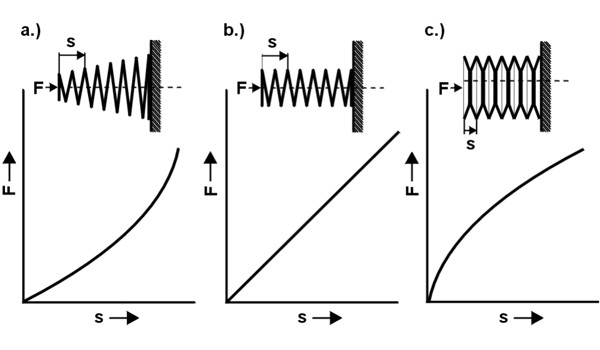

Spring characteristic

The spring characteristic shows how the metal spring behaves at work. It describes the relationship between spring force ( F ) and spring deflection ( s ). Depending on the type of spring or the spring system used, a distinction

Information compression springs

Compression springs or coil springs are mechanical energy accumulators that absorb forces when they are compressed and release the forces when they are released. Gutekunst Federn offers quick selection and procurement of compression springs in its catalog program on Federnshop.com