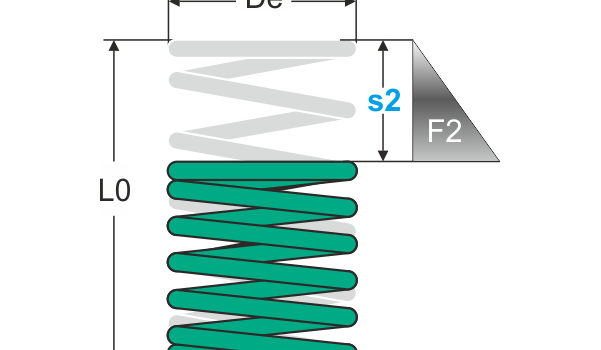

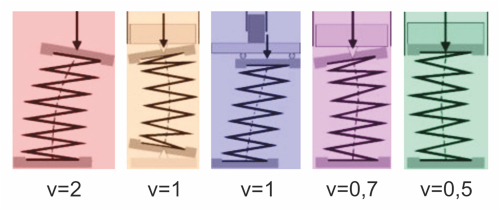

The tolerances for compression springs are defined in accordance with DIN 2095 (DIN EN 15800). Quality grade 1 describes the smallest tolerance zone (higher product price) and quality grade 3 the largest tolerance zone. Our compression springs are manufactured to

Tolerances compression springs