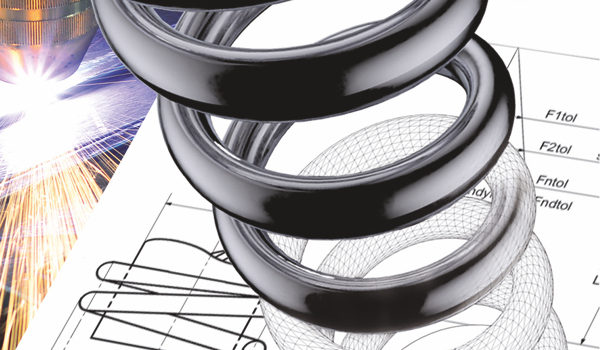

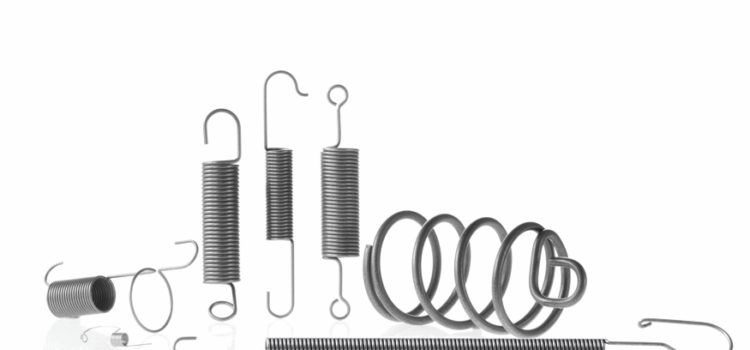

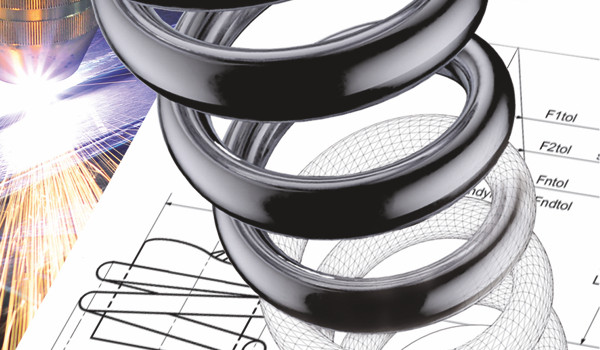

What exactly does the term “technical springs” mean? Which types of metal springs are they meant and for which force states and applications are they used? Gutekunst Federn and Gutekunst Formfedern will briefly address these questions and other properties in

Technical springs – compact knowledge