Selecting or requesting the right metal spring for the desired application is not always easy. In addition to the type of spring, shape, dimensions and force characteristics, environmental influences and special properties often have to be taken into account. In addition to its catalogue range, Gutekunst Federn therefore also offers the possibility of individual spring enquiries. If, for example, you cannot find a suitable metal spring in the catalogue range, either click on the request symbol ![]() for a similar catalogue article in order to individualise it, or go directly to the Gutekunst spring enquiry and send the desired spring data there for design and quotation. No matter how you proceed, you will simply find the right metal spring at Gutekunst. To assist you, the following is a brief overview of the most important parameters for the selection and enquiry of compression springs, extension springs and torsion springs. Information on other types of springs can be found in the Products menu.

for a similar catalogue article in order to individualise it, or go directly to the Gutekunst spring enquiry and send the desired spring data there for design and quotation. No matter how you proceed, you will simply find the right metal spring at Gutekunst. To assist you, the following is a brief overview of the most important parameters for the selection and enquiry of compression springs, extension springs and torsion springs. Information on other types of springs can be found in the Products menu.

First of all, some basic information about compression springs, extension springs and torsion springs:

Compression springs

Compression springs are by far the most commonly used. This is not only due to the direction of the force application, but mainly due to the superior loading characteristics of the compression spring. This is because compression springs are better able to handle greater forces, even in fatigue applications with over107 load cycles. In addition to the large selection of materials for the various applications, the variety of uses for the compression spring can be easily extended with a wide range of surface treatments. Due to the performance data of the compression spring, in some cases it even makes sense to convert a tension spring application to a compression spring.

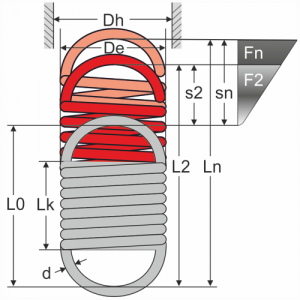

Tension springs

Tension springs are the second most commonly used. Wherever the force has to be applied by tension rather than compression, there is no getting around the tension spring. In particular, the special design with the eyelets on both sides involves some risks that must be taken into account in the tension spring design. Also, the fact that the tension spring completely loses its spring force in the event of a spring fracture should be taken into account when using a tension spring. Due to the adjacent coils, surface treatment of the tension spring is only possible with increased effort.

Schenkelfedern

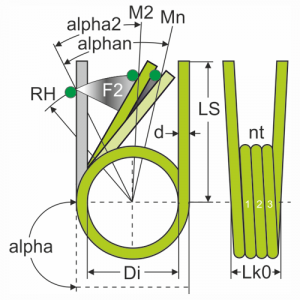

Torsion springs are used for rotary movements, i.e. wherever bending stress occurs. The spring body of a torsion spring is always cylindrical with a linear spring characteristic and should only be loaded in the coil direction. The leg shape of the leg spring is individually adapted to the installation situation for optimum force transmission. As with the extension spring, it is also difficult to apply further properties to the torsion spring by means of a subsequent surface treatment due to the coils lying next to each other.

Table of Contents

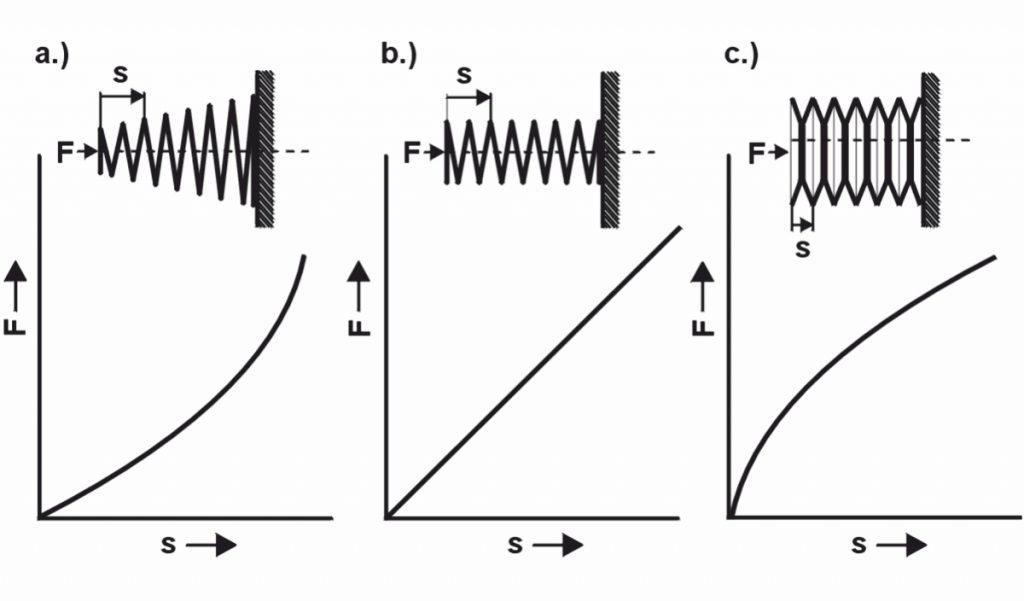

1. determination of spring characteristic

Basically, metal springs are judged according to their characteristic curve. The spring characteristic is the character of the metal springs. It represents the ratio of the spring force “F” to the spring travel “s”. Depending on the spring type, spring design, coil spacing and spring system, linear, progressive or degressive spring characteristics can be generated.

In the case of a linear spring characteristic (Fig. b: cylindrical spring), the force is delivered evenly, in the case of a progressive characteristic (Fig. a: conical spring), the force development increases with the increase in load, and in the case of a degressive characteristic (Fig. c: disc spring), the force development decreases with the load.

However, 95% of the springs used are cylindrical metal springs with a linear spring characteristic. Therefore, all standard springs from the Gutekunst Federn catalogue range have a cylindrical design with a linear spring characteristic. If you are interested in conical compression springs or conical extension springs, please visit blog.federnshop.com for more information.

2. specifications for the matching metal spring

After the character of the metal spring and the type of spring have been determined by means of the spring characteristic curve and the force curve, the following properties must be determined for optimum selection and design:

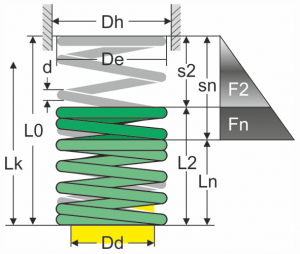

2.1 Dimensions and force data of the metal spring

What are the dimensions of the installation space in which the metal spring is to be inserted? What diameter “De” and what length “L0” may or must the metal spring have so that it can be installed? The required spring forces (F*) at the various stress conditions, according to the spring travel (s*) or the tensioned spring length (L*), are then determined for these construction dimensions. In most cases, the metal springs are installed preloaded, i.e. the spring already generates a certain preload force at rest. This force is called “F1” (preloaded spring force). The required spring force in the tensioned state, “F2” (tensioned spring force), must also be specified. The associated spring deflections “s1” and “s2” or spring lengths “L1” and “L2” are then also specified for these two spring forces. Especially with dynamic loads, the spring stroke “sh” is important, which describes the spring travel between “s1” and “s2” or between “L1” and “L2”. The smaller the spring stroke, the better the dynamic load capacity of the metal spring.

2.1 Spring material or basic properties

Does the metal spring you are looking for have to be corrosion-resistant, resistant to aggressive acids or additionally electrically conductive? Is it used in the food industry or is it supposed to be medically pure? To determine the suitable spring material, the ambient medium and the intended use are decisive. In addition, the operating temperature influences the selection of the appropriate spring material. There are preferred spring steels for low temperature and for high temperature applications. Especially in high-temperature applications, the relaxation of the spring material must be taken into account in the force design, because an increasing loss of force occurs with increasing temperature and load duration.

Which spring steel is the most suitable and whether an additional surface treatment is necessary can be derived from these basic properties. For detailed information on spring materials and surface treatments, please visit blog.federnshop.com. In case of uncertainty regarding the spring material or surface treatment, it is sufficient to specify the basic property (e.g. “acid resistant”) together with the required number of load cycles (total service life), the operating environment and the operating temperature in the spring enquiry. The optimum design is then carried out by the specialists at Gutekunst Federn.

If you need further information on the subject of metal springs or if you require an expert design with a non-binding price quotation for your technical spring application, then simply send us the requirements, a drawing or CAD data of the desired metal spring, regardless of the technical spring in question, using the Spring request or by e-mail to service@gutekunst-co.com. Or you can contact the technicians at Gutekunst Federn, metal springs made of spring steel wire, directly by telephone on (+49) 07123 960-192, or Gutekunst Formfedern, metal springs made of flat material, by telephone on (+49) 07445 85160.

For more information: