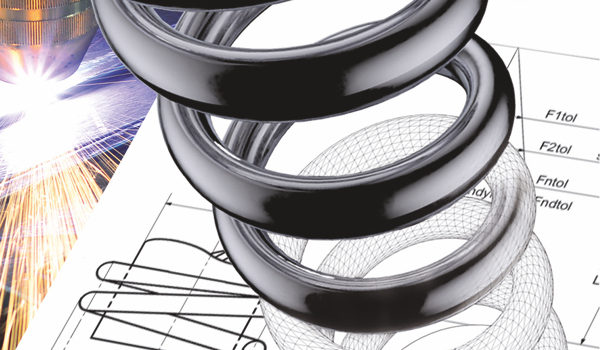

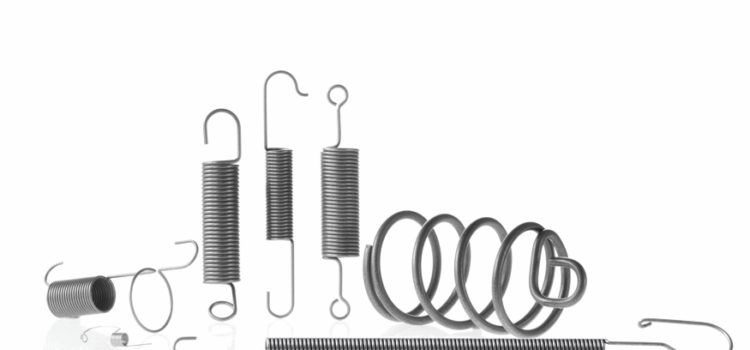

Circle at a speed of approximately 28,000 km / h Gutekunst compression springs Earth orbit on the international space station ISS. This makes them probably the fastest compression springs in use. Gutekunst feathers supplies these compression springs to the company

Compression springs in space