Compression springs, extension springs and torsion springs are typical C-parts for most companies: They are not the focus of the procurement process, but are used in almost all technical applications. The requirements for the springs are very versatile and individual.

Metal springs for extreme cases

Whether in corrosive liquids, at High temperature applications or at lowest temperatures , with dynamic or static loads, compressive, tensile or bending loads: With the Design of the metal spring in extreme cases there is more to be done than

Design of metal springs – Part 2 “Calculation

In the first part of this two-part series Gutekunst Federn informed about the basics of spring design. In this second part you will find the concrete calculation data for the design of compression springs, extension springs and torsion springs (torsion

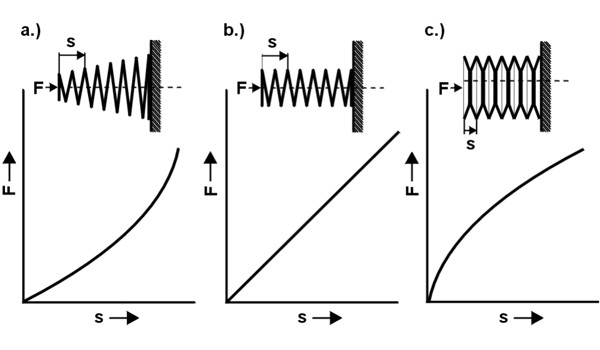

Spring characteristic

The spring characteristic shows how the metal spring behaves at work. It describes the relationship between spring force ( F ) and spring deflection ( s ). Depending on the type of spring or the spring system used, a distinction

Information torsion springs

Leg springs, also known as torsion springs, are mechanical energy stores that absorb a torque when the legs are angularly / rotationally moved, which they release again when they are released. Gutekunst Federn offers quick selection and procurement of torsion