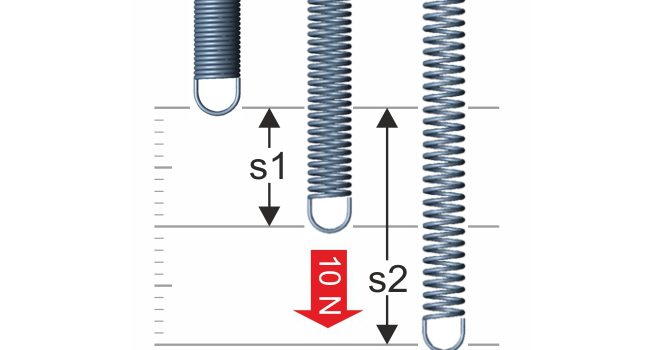

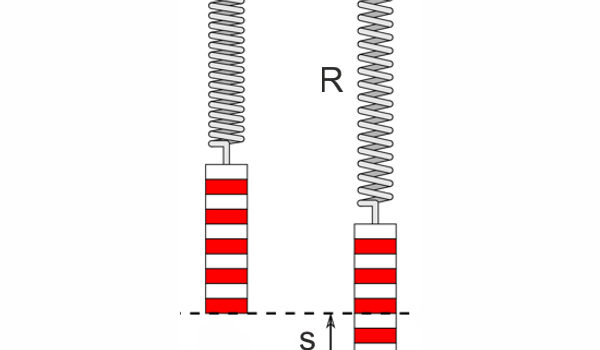

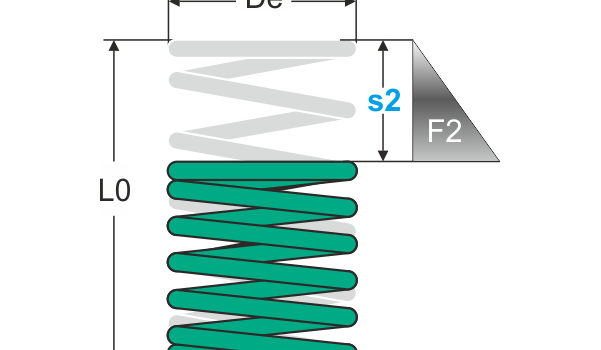

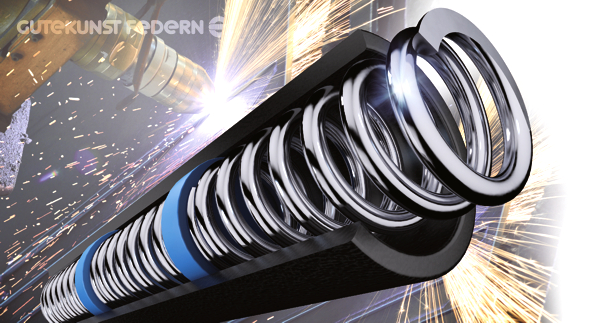

Which spring steel wire is suitable for which application? Spring steel wire compared to other steels has a higher strength and can be up to a certain voltage ( Elastic limit “Rp” ) are deformed. With this property, the spring

Spring steel wires and their properties