The spring force – also known as the tension force – arises when an elastic body is pulled apart or compressed – for example one Metal spring made of spring steel wire . An opposing force acts in it, which

Calculate spring force

The spring force – also known as the tension force – arises when an elastic body is pulled apart or compressed – for example one Metal spring made of spring steel wire . An opposing force acts in it, which

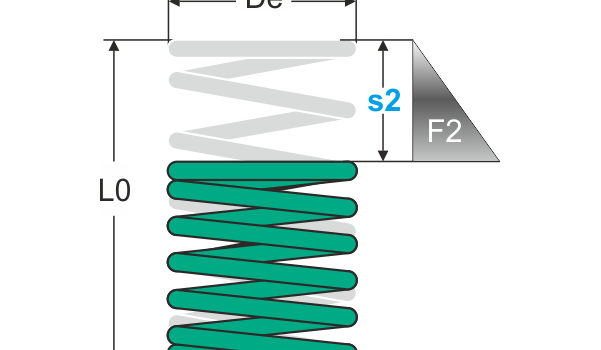

In the spring work “ W “ becomes through when tensioning the spring Deformation work potential energy generated and stored, which is released again when the spring is released. The spring work always results as the area below the Spring

Spring systems are spring-technical applications made up of several individual springs, which together realize special tasks. These individually designed spring systems can be designed for a wide variety of applications. By selecting and arranging different springs, practically every desired force

Compression springs, extension springs, torsion springs, cotter pins, flat springs, shaped springs and many more types of springs – the world of metal springs is complex and extensive. Technical springs perform permanent work in countless products in secret. Now imagine

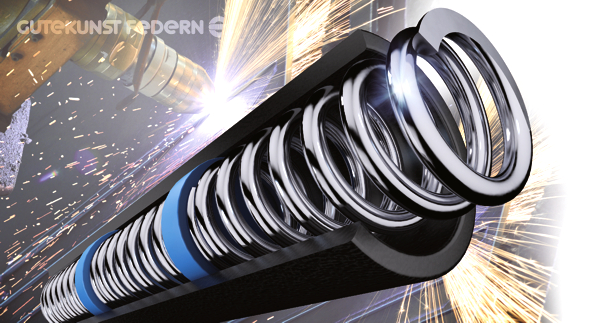

Compression springs , partly too Tension springs and Leg springs The subsequent treatment of their surfaces gives them additional properties – depending on the application, they become, for example, harder, more rustproof or more heat-resistant. Gutekunst feathers offers for his

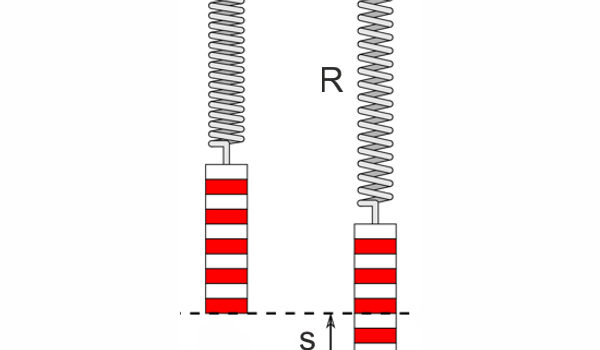

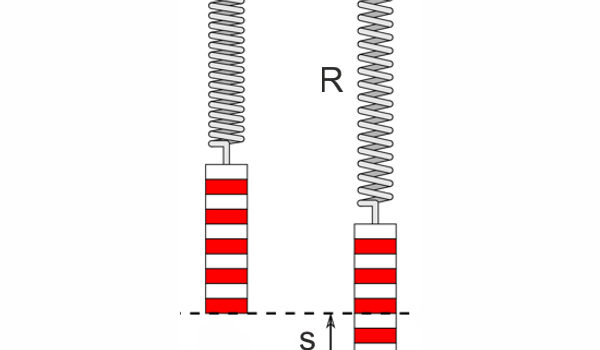

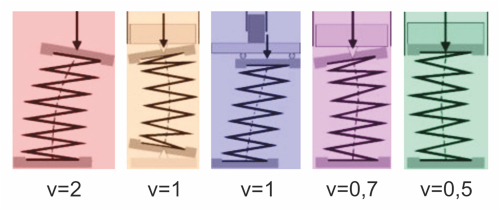

Depending on the size, guidance and bearing, compression springs are at risk of buckling. When guided by mandrel or sleeve, the spring cannot buckle. In other cases, it depends on the design of the bearing(EN 13906-1 / 9.14). The spring

Below is the summary of the basics about Spring design of Compression springs , Tension springs and Leg springs . Technical springs are still one of the most important machine elements today and are used successfully in vehicles, precision mechanical

Selecting or requesting the right metal spring for the desired application is not always easy. In addition to the type of spring, shape, dimensions and force characteristics, environmental influences and special properties often have to be taken into account. In

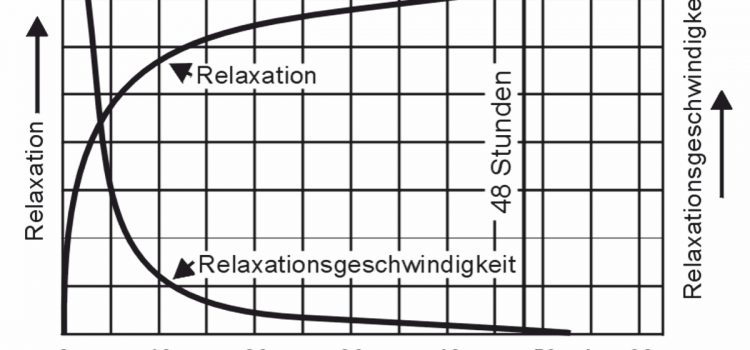

In metal springs, a loss of force occurs under permanent tension and higher temperatures, which is called relaxation. This loss of force increases with increasing temperature and load duration. This loss of force is given as a percentage of the

Always the right compression spring, extension spring and torsion spring – from the quick spring selection in the catalog, to the design and calculation of individual metal springs, to the CAD data generator for standard springs and freely calculated metal