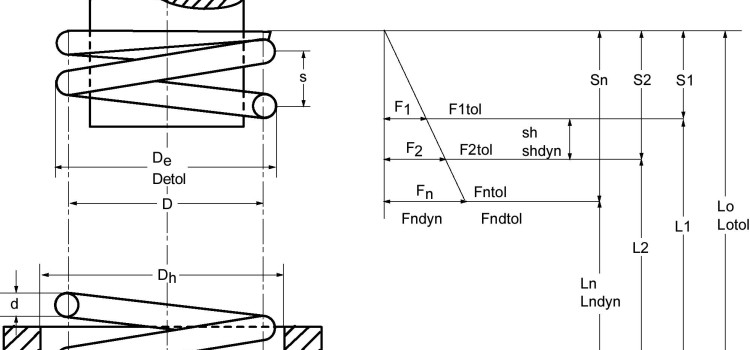

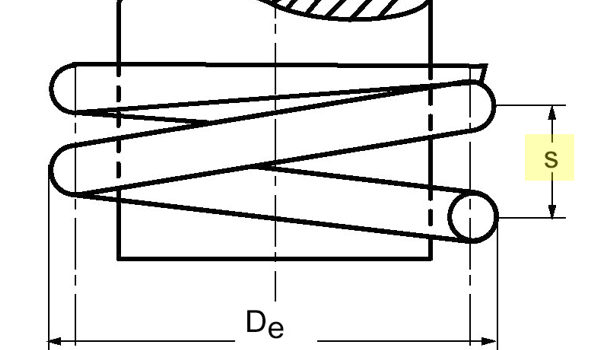

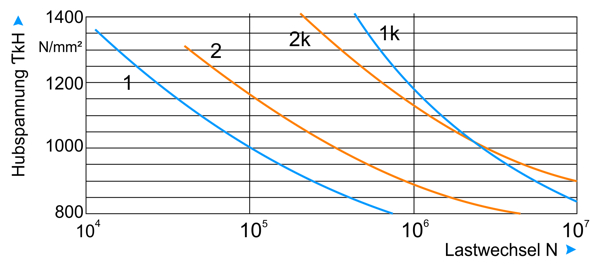

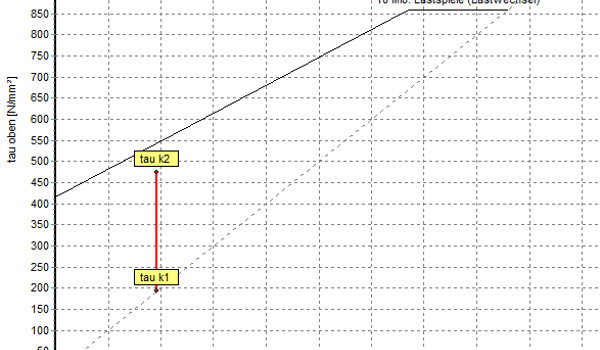

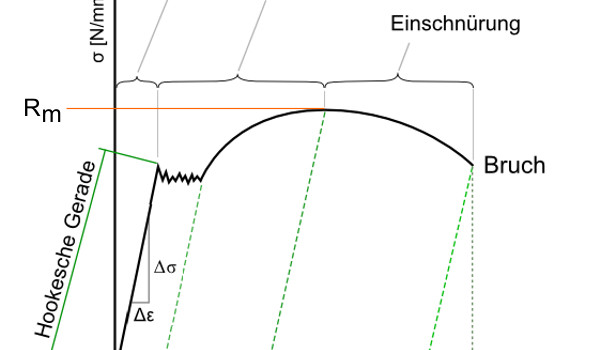

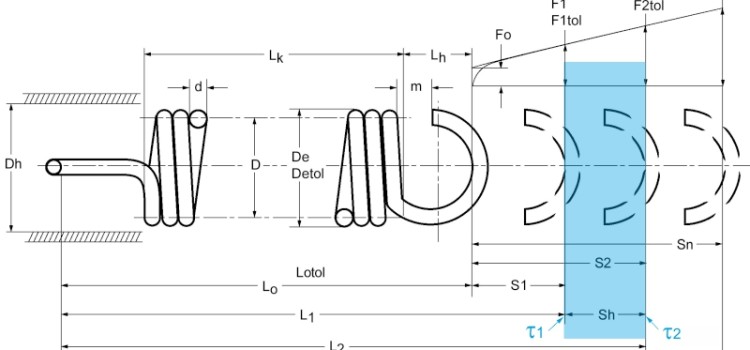

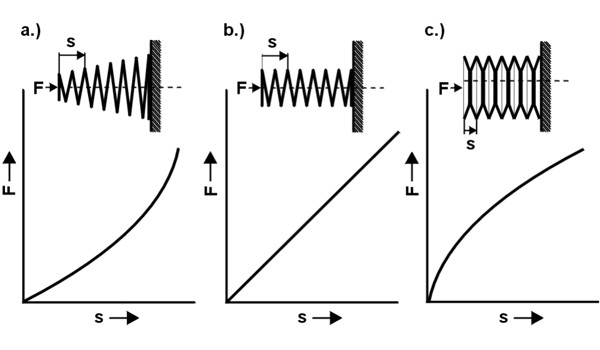

Every spring design of a compression spring consists of two stages : 1. The proof of function, with the verification of the dimensions, spring rate, forces, spring travel and vibration behavior. 2. The proof of strength, with the verification of

Function and strength verification for compression springs