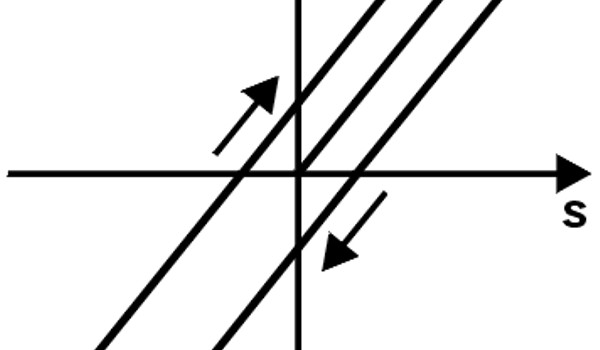

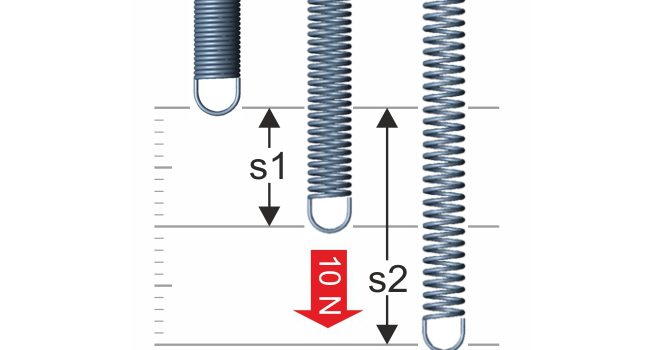

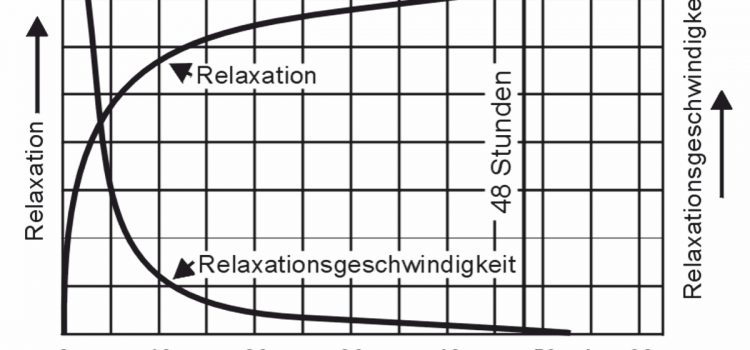

When the metal spring is tensioned, work is done, which is then released again when the tension is released. The spring work (W) always results as the area below the spring characteristic. The suspension behavior of steel springs can be

Hysteresis loop