Always the right compression spring, extension spring and torsion spring – from the quick spring selection in the catalog, to the design and calculation of individual metal springs, to the CAD data generator for standard springs and freely calculated metal springs.

Compression springs, extension springs and torsion springs are not the focus of the procurement process as typical C-parts, but they are required in almost all technical applications.

Compression springs, extension springs and torsion springs are not the focus of the procurement process as typical C-parts, but they are required in almost all technical applications.

Metal springs are small force accumulators that absorb energy when loaded and release it when unloaded. Depending on the requirements, each spring is made of spring steel wire on a spring coiling machine. The metal spring is therefore a purely mechanical product. This means that the spring design is of great importance, because it is not possible to make subsequent changes via a software update or a function adjustment.

The questions in spring design are manifold: compression, tensile or bending load? Standard or extremely resistant? With linear or with progressive characteristic? Small or large? Straight or with shaped ends?

Table of Contents

Metal springs from the catalogue or individually according to requirements

It is therefore important for the spring manufacturer to be able to react flexibly to customer requirements and to supply individual metal springs in addition to the standard springs that are quickly available from stock. Gutekunst Federn offers exactly this flexibility through its extensive catalogue programme with 12,603 spring sizes from stock and individual spring production up to 12 millimetre wire thickness. If one of the catalogue springs in the classic cylindrical design in standard steel EN 10270-1 and stainless steel 1.4310 fits, then the spring requirement is quickly covered.

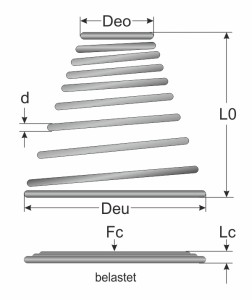

In special applications, the metal spring is precisely matched to the installation situation and the individual requirements: as a cylindrical spring, conical spring, barrel spring or beehive spring with variable spring characteristics and coil spacings. The design and calculation of compression springs, extension springs and torsion springs is carried out according to DIN EN 13906 with various design aids and on the basis of Gutekunst Federn‘s experience.

Consequently, the development of a metal spring requires special attention and also special design aids such as a spring calculation program, useful information and design data in the form of CAD data and diagrams. And also, of course, an experienced spring manufacturer who can achieve the required properties by properly coiling spring steel wire.

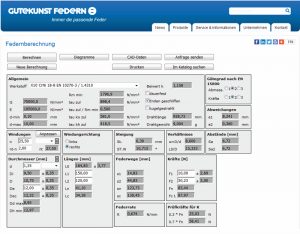

Individual spring calculation with WinFSB

For this reason, Gutekunst Federn has developed its own spring calculation program for compression, extension and torsion springs for the optimum design and calculation of individual metal springs, taking into account the German standard for springs 13906-1:2013. The calculation can be carried out according to a wide range of variants, for example according to displacement and force ratios or simply according to construction properties.

For this reason, Gutekunst Federn has developed its own spring calculation program for compression, extension and torsion springs for the optimum design and calculation of individual metal springs, taking into account the German standard for springs 13906-1:2013. The calculation can be carried out according to a wide range of variants, for example according to displacement and force ratios or simply according to construction properties.

The spring calculation program calculates the desired metal spring with all important parameters, additionally offers various diagrams (such as the spring characteristics and the Goodman diagram) as well as a direct interface to the Gutekunst CAD generator for 2D and 3D CAD data. The spring calculation program WinFSB is freely available to everyone as an online spring calculation and offline spring calculation (PC version) at www.federnshop.com.

CAD generator for standard springs and individual metal springs

Design engineers work exclusively with CAD programs. This fundamentally reinforces the trend towards standard products. Here, the CAD data is already available and the designers do not lose any time: Simply download the data from the provider’s website and import it into the design program. However, in addition to its CAD data offer for the standard spring program, Gutekunst Federn also offers direct CAD data for individually calculated metal springs.

Design engineers work exclusively with CAD programs. This fundamentally reinforces the trend towards standard products. Here, the CAD data is already available and the designers do not lose any time: Simply download the data from the provider’s website and import it into the design program. However, in addition to its CAD data offer for the standard spring program, Gutekunst Federn also offers direct CAD data for individually calculated metal springs.

This means that any designer can calculate the spring of his choice using the WinFSB spring calculation program and then download it immediately in 2D and 3D format. For individual CAD data, it is sufficient to carry out a simple construction dimension calculation according to wire thickness “d”, outer coil diameter “De”, untensioned length “L0” and number of coils in order to obtain the required CAD data. Test immediately, go to the spring calculation at www.federnshop.com.

You will find the complete spring catalog with shop and CAD data generator as well as the individual spring calculation program www.federnshop.com .

Should you require an individual spring design, simply email us the key data of the required metal spring to service@gutekunst-co.com or contact our technical department by telephone on (+49) 035877 227-11.

For more information: