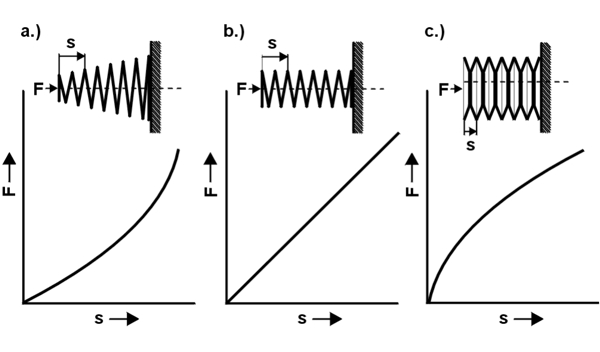

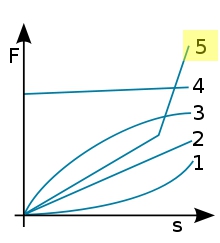

The spring characteristic shows how the metal spring behaves at work. It describes the relationship between spring force ( F ) and spring deflection ( s ). Depending on the type of spring or the spring system used, a distinction is made between linear ( b ), progressive ( a ), degressive ( c ), or combined spring characteristic.

A progressive spring characteristic ( a ), which increases the force as the deflection increases, is obtained with a conical spring design and with one mixed circuit of single spring n. A linear spring characteristic ( b ), which releases the force evenly as the compression increases, is obtained with cylindrical design and with one row or parallel connection . A degressive spring characteristic ( c ), which reduces the force as the compression increases, can be achieved with a disc spring column .

A combined spring characteristic ( 5 ), which abruptly changes the force properties in certain compression states, can be achieved with combined spring designs and special rows – or mixer circuits can be achieved by single springs. The spring characteristic ( 4th ), with a high preloaded force and a low force curve, is achieved with a soft preloaded spring

The spring rate ( R. ) is the slope of the spring characteristic in the spring diagram. With a linear spring characteristic, the spring rate is constant. Springs with a curved spring characteristic have a variable spring rate. With a linear spring characteristic, the following applies:

With compression springs and tension springs

\Large R = \frac{F2 - F1}{s2 -s1}

With torsion springs / torsion springs

\Large R = \frac{M2 - M1}{\alpha2 -\alpha1}

For more information:

- Calculation of the total spring rate at parallel -, rows – and mixer circuits